EPM Tooling Co., Limited is located in No. 49, 2nd industrial zone, Houting village, Shajing town, Shenzhen city. 518104 P.R.C

EPM Tooling covers an area of more than 1,800 square meters and has more than 60 employees.

EPM Tooling is a well-equppied mold shop, most machines are imported from Japan and Taiwan.

EPM Tooling has a strict QC system to ensure the mold quality, the QC system never allow the unqualified workpiece flow to next machining procedure.

EPM Tooling has an excellent project team to manage the projects from the begining to the mold shipment. All of them have at least 8 years mold manufacture working experiences, they can speak English fluently.

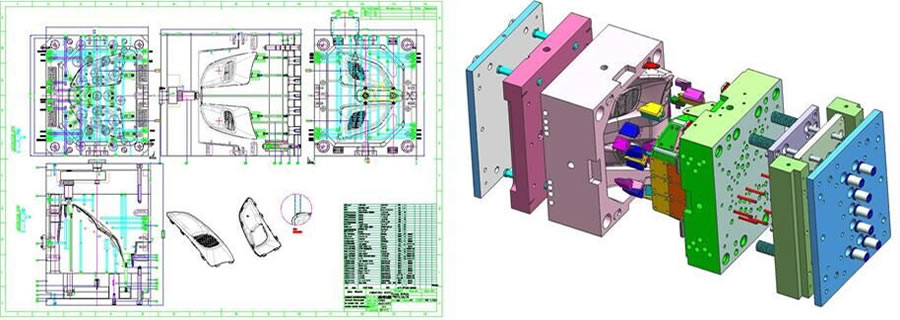

EPM Tooling has a powerful design team to provide the best mold design to our client. They have rich mold design experiences, fast and perfect.

EPM Tooling has a high capacity production team, they work 24 hours per day, 6 days per week, 2 shifts.

EPM Tooling core team is our management team, they are each team leaders. The team only has one goal, take each mold as their own baby.

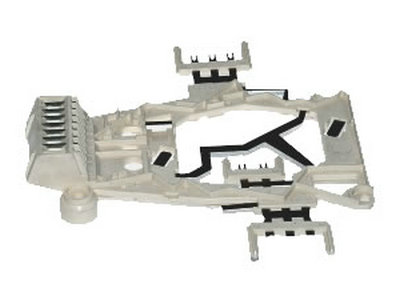

EPM Tooling machining capacity, maximum mold size 2 meters, maximum mold weight 15 Tons, 40 sets mold per month.

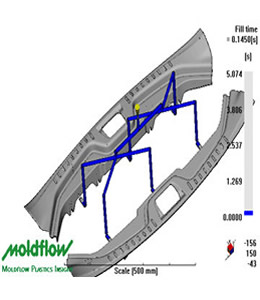

EPM Tooling has 8 experienced design engineers for part & mold design. All of them have over 10 years experience in plastic product and mold making and designing, we can offer consultative knowledge and expertise during reviewing DFM stage, it helps you to save significant engineering time and cost. With our advanced CAD/CAM/CAE systems, such as Pro-Engineer, Solid works, UG, Cimarron, Mold Flow, Auto CAD in mold design, manufacture and analyses, we can provide you most of different types of files (DXF, DWG, PRT, X_T, IGES, STEP, SLDPRT, etc). We can accept your initial concept in a wide range of formats from rough paper drawings to 2D or 3D CAD models. We can provide you Mold Flow Analysis including analysis of wrap, cooling, filling time, temperature, air trap, welding lines, shear rate, shrinkage etc. Generally, we can complete all mold design drawings in 2-4 days by our advanced 2D&3D CAD/CAM software.

Certificate

Cooperation client

Partner suppliers

Address: No. 49, 2nd industrial zone, Houting village, Shajing town, Shenzhen city. 518104 P.R.C

Tel:+86 136 3273 9894 Email:Daniel@epm-tooling.com

We do our best for your plastic moulds